What is MRP in Supply chain management?

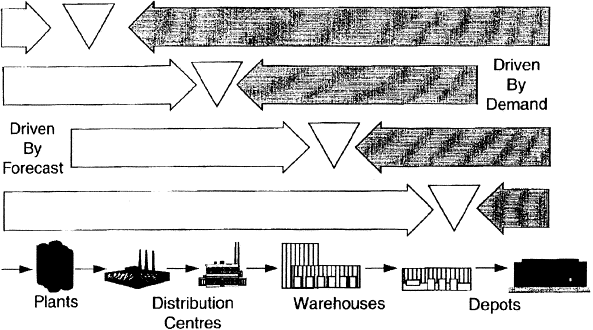

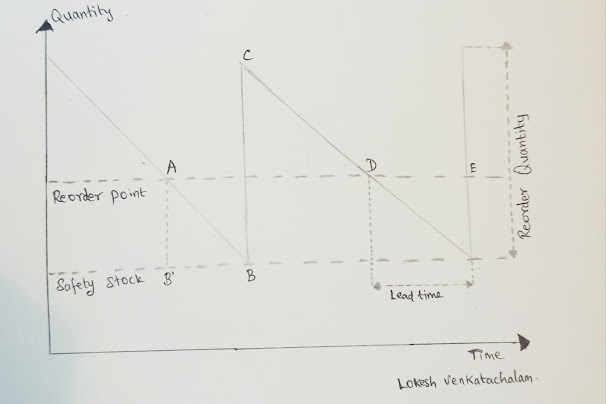

MRP is an abbreviation of Material Requirement Planning. As in its name, it manages the materials required for the production activity. It is an operation or System done by software to manage and optimise the production activity, especially in the manufacturing industry. MRP will Plan, Schedule, and Manage the Inventory during the manufacturing process. It calculates the materials and components needed to manufacture a product. It takes the data of inventory stocks, on-hand, and sometimes safety stock to figure the required materials for the upcoming product they are going to produce. Initially, it starts to calculate the demand for the upcoming time period (or) the number of orders the company has from their customer, then it eliminates that with on-hand stocks in inventory, and later that MRP will finalise the exact number of products how much they are going to produce. For that production, they need additional parts to finish the product. So, if they need those additional parts,...

.jpeg)