First of all, reorder is the term we use for replenishment in inventories when required. The replenishment or reorder will be considered by different terms, different conditions, and different times. It varies from one inventory to another based on the nature of the inventory.

Nature of inventory means the placement of inventory, goods they are maintaining, the equipment they are using, manpower they have, climate and weather, demand they have, occurrence of the demand, and so on.

What is Reorder point and Reorder quantity?

Reorder Point is the pre-decided number of units the inventory left on hand at which you need to reorder more units from the suppliers to fulfil the demand or the inventory will run out of inventory to fulfil demand.

Reorder Quantity is the number of units the inventory need to order when the inventory level obtains the reorder point. The reorder quantity is mostly pre-decided and sometimes dynamic according to the demand.

|

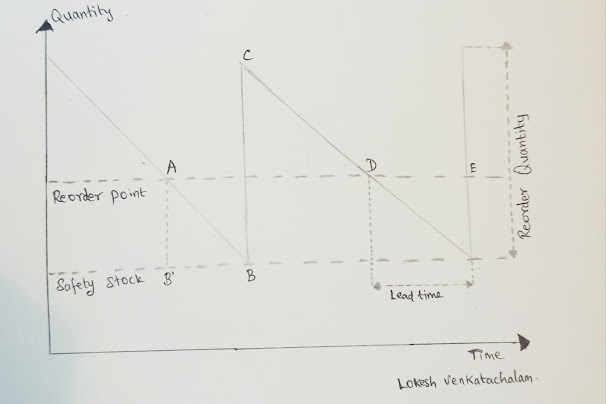

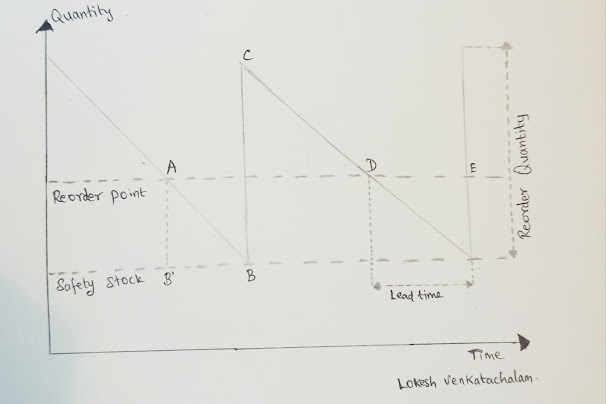

Reorder Point and Reorder Quantity

The above will help you to explain the graphically understand the reorder point and reorder quantity, actually when the inventory level reaches the reorder point it generates some units of goods to reach the required inventory level.

Here, the reorder point and reorder quantity should be calculated based on the demand of the period of time. So we can calculate it with some formulae, prior that we need to know, what is Safety stock? Safety stock is an additional quantity of a product that is kept in the warehouse to avoid running out of stock. It acts as a buffer against demand changes.

To find the Reorder point there are 4 formulae we have,

i) when the demand is variable and lead time is constant

𝑆𝑆 = 𝑍(𝜎𝑑 × √𝐿𝑇)

𝑅𝑂𝑃 = 𝜇𝑑 × 𝐿𝑇 + 𝑍𝑍(𝜎𝑑 × √𝐿𝑇)

ii) when the lead time is variable and demand is constant

𝑆𝑆 = 𝑍 × 𝑑𝐷 × 𝜎𝐿𝑇

𝑅𝑂𝑃 = (𝑑𝐷 × 𝜇𝐿𝑇 ) + 𝑍 × 𝜎𝐿𝑇

iii) when both lead time and demand are variable

𝑆𝑆 = 𝑍√((𝜇𝐿𝑇 × 𝜎𝑑

2

) + (𝜇𝑑)

2 × 𝜎𝐿𝑇

2)

𝑅𝑂𝑃 = (𝜇𝑑 × 𝜇𝐿𝑇) + 𝑍 × 𝜎𝐿𝑇

where,

SS =Safety stock σ dLT = Standard division of demand during the lead time σd= Standard deviation of demand per day LT=Lead time Z= Service level ROP= Reorder point μdLT= Demand mean during the lead time μd= Average daily demand dD= Daily demand σLT= Standard deviation of lead time in days μLT= Average lead time

iv) this will be the common and easy formula for all

Reorder point = (Average demand

* average lead time) + Safety stock

To find a Reorder Quantity

Reorder

quantity = Average daily usage * average lead time

Meanwhile,

To calculate Safety stock the common formula is

Safety stock = ( max. daily usage*max. lead time in days) - (avg. daily usage*avg. lead time in days)

Example

Reorder point

Average

Daily Usage = 1,250.7

Average

lead time = 1 day

Safety

stock = 4,378 Reorder Point = (Average Daily Usage x Average Lead Time in Days) + Safety Stock

So,

Reorder

point = (1,250.7 * 1) + 4,378

Reorder

Point = 5,629 Reorder QuantityAverage

daily usage = 1,250 Average

lead time = 5 days

Reorder

quantity = Average daily usage * Average lead time

Reorder

quantity = 1,250.7 * 5 Reorder quantity = 6,253

EOQ (Economic Reorder Quantity) formula

EOQ stands for Economic Order Quantity. EOQ is a tool used to determine the volume and frequency of orders required to satisfy a given level of demand while minimizing the cost per order. Sometimes it also used to calculate reorder quantity.

EOQ = square root of: [2(setup costs)(demand rate)] / holding costs

Posted by,

|

Comments

Post a Comment